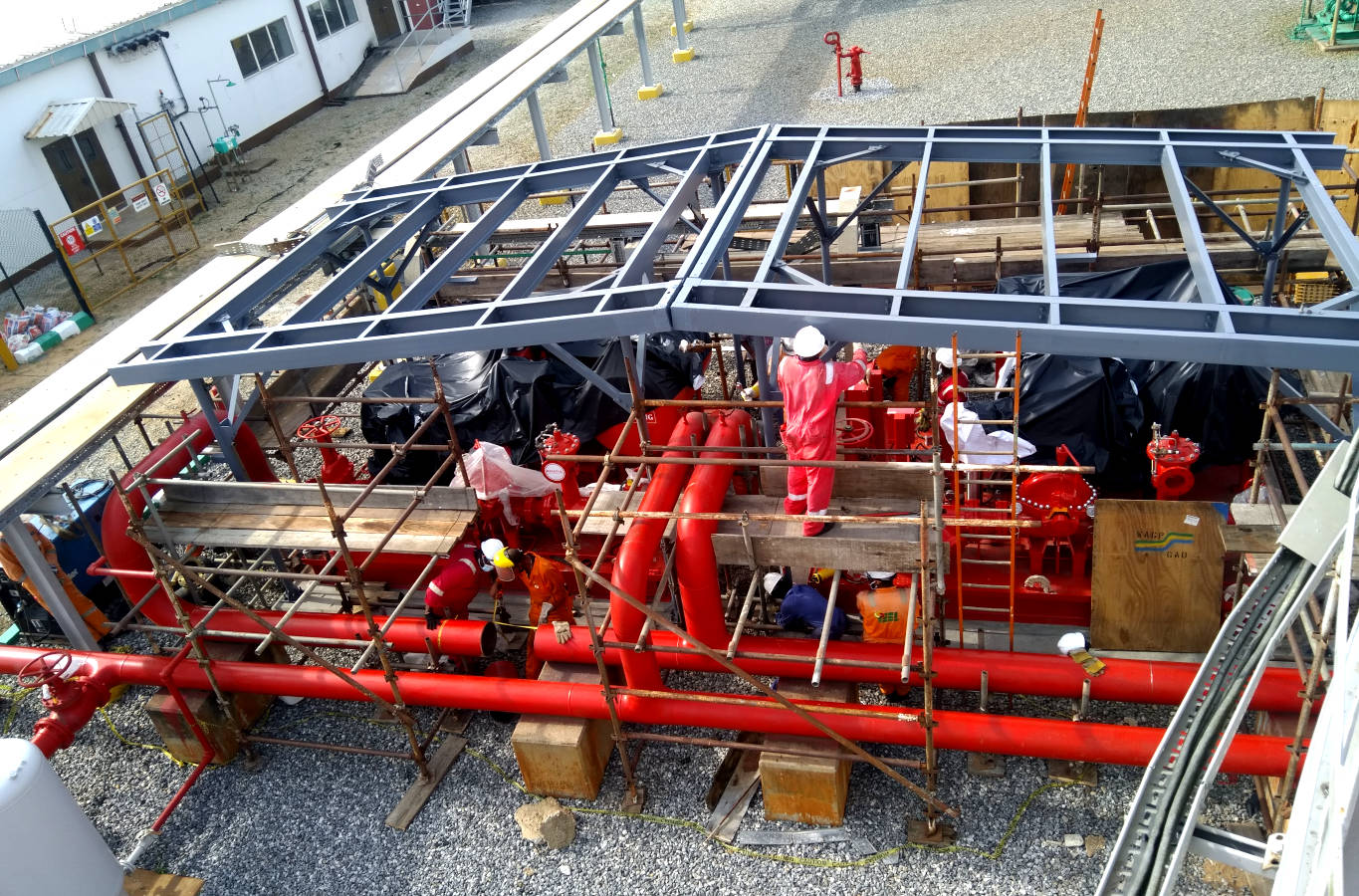

IESL provides specialists and engineering support in all areas of Asset Integrity Management, Facility Inspection, and Verification. These embrace the following: design, process safety, QAQC technical audit, inspection testing and maintenance, operational and process support, corrosion, metallurgy, and risk analysis to provide you with Total Quality Assurance. We leverage experience and industry best practices to deliver the solutions you require.

Asset Integrity

IESL help its clients maintain their assets, ensure productivity, reliability, and safety, reduce risks, and meet all relevant industry regulations through the following service offerings.

-

Management of asset integrity contracts and project documentation, records, and as-built documentation.

-

QAQC and Inspection Monitoring during the line pipe and umbilical tubing procurement.

-

Inspection of materials and equipment as well as verification of wielding specifications in accordance with wielding documents, to mention a few.

Risk Based Inspection

Our risk-based inspection services include:

-

Assessment of process operations that will impact production, operation, material integrity and degradation rates

-

Development of a corrosion management plan

-

Determination of the full lifetime spectrum of your assets

-

Gap analysis of asset operations and maintenance programs

-

Identification of operational risks, using recognized industry codes and standards, to mention a few

Facility Condition Assessment

Our Facility Condition Assessment provides our clients with accurate, objective data about the health of assets and facilities so that capital investments can be targeted to meet the goals of stakeholders. These goals could include 24/7 dependable operation, reduced risk, increased service capacity, or more growth.

Advanced Metallurgical Evaluation

Our experts have a thorough knowledge of casting, welding, brazing, thermal spray, and heat-treatment processes, as well as special expertise with superalloys, electrical conductors, and composites. Metallurgical evaluations include Braze analysis, Case depth, Casting evaluations, Coating characterization, Corrosion susceptibility, Failure analysis, Fractography, Image analysis, and Metallographic evaluation, to mention a few.

Corrosion Engineering and Risk Assessment

Our services combine technical knowledge, expertise and experience to provide optimum solutions; assuring the corrosion prevention and monitoring of assets and infrastructure with typical applications such as:

-

High-Temperature Non-Intrusive Corrosion Monitoring

-

Traditional Corrosion Monitoring

-

Retrofit Corrosion Monitoring Systems

-

Corrosion & Sand Monitoring Status and Performance

-

Data Assessment, Management and Verification

-

Sand and Other Particle Detection

-

Grit blasting/Sandblasting and Coating Services, to mention a few

Non-Destructive Testing (NDT) Services

We offer standard and advanced NDT services, onshore, offshore & subsea. We deliver NDT services to all industries during fabrication, in-service as well as during shutdowns and maintenance in the following areas:

-

Ultrasonic Testing (UT)

-

Radiography Testing (RT)

-

Visual Testing (VT)

-

Eddy Current Testing (ET)

-

Penetrant Testing/Dye Penetrant Testing (PT/DPI)

-

Magnetic Particle Testing (MPT)

-

Leak Testing (LT)

-

Quality Management Services

-

Welder/Welding procedure

-

Construction Supervision

-

Third-party inspection and verification

-

Mechanical Testing

Rope Access

IESL’s rope access service offering helps the client:

-

Have essential inspection, testing and survey work carried out on assets that are hard to reach

-

Benefit from a cost-effective alternative to traditional access methods, such as scaffolding or mobile elevated working platforms

-

Have inspections carried out quickly and safely with minimal disruption to other services

All Our Services

Working Hours

- Weekdays 7:00 am - 4:00 pm

- Saturday Closed

- Sunday Closed